When you purchase through links on our site, we may earn an affiliate commission. Here's how it works. |

Life was grand before IBIS (in body image stabilization) because camera manufacturers could simply slap a hunk of metal onto the back of the sensor, and things would stay cool, as heat would transmit through the camera body chassis and dissipate.

However, when the camera is stabilized, the weight and size of the platform that has the sensor attached have to remain lightweight. The larger the platform, the more mass, and the more mass requires more energy to move. This makes it harder for IBIS to react to motion, and also for IBIS not to drain your battery before you have even taken a photo.

So the manufacturers tend to make those sensor platforms now as small and light as possible for IBIS, but this, on the other hand, makes heat problematic, as there's not enough means for heat to move away from the sensor because it's not fixed to the camera body.

Canon has patented metallic strips that transmit heat away from the camera’s sensor, and this looks to be an expansion on this.

Essentially, in your camera, there are flexible strips, some of them transmit the signals to and from the sensor, such as thin ribbon cables that have a high degree of flex, but there are also others that have the primary responsibility of shunting heat away from the sensor as quickly and easily as possible.

This will never be as easy as a directly attached sensor to a camera frame, which is why you tend to see record times more problematic on cameras that have IBIS.

Not only does heat affect the long-term stability of the sensor, even for stills, having a warm or hot sensor will degrade the sensor’s high ISO noise capabilities, which is why most astrophotography sensors are actively cooled. The cooler the sensor, the less noise.

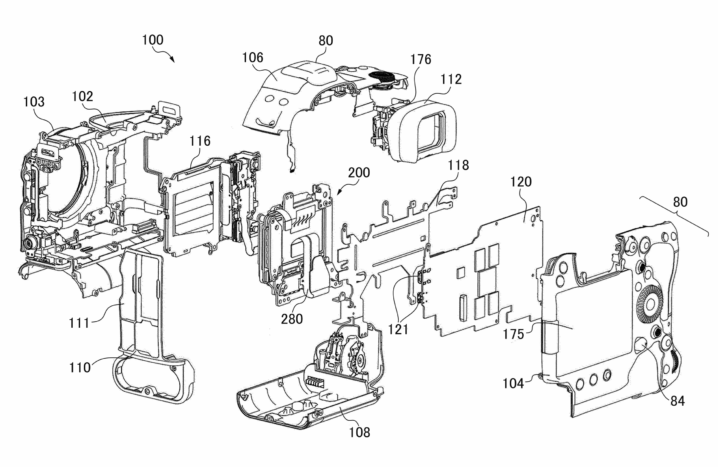

Canon has recently published three patent applications dealing with this, and all of them go into a great deal of mechanical engineering details on the sensor assembly and camera body. It’s an insight into what Canon does under the hood to attempt to deliver the best possible camera system to us, so we can complain about it – naturally.

Patent Publication No. 2025-176889

Canon discloses the problem that they are looking to resolve:

In recent years, imaging devices that perform shake correction by moving the imaging element in a direction perpendicular to the optical axis to improve image quality have become widespread. Even in imaging devices that perform shake correction, sufficient heat dissipation is required because heat generated in the imaging element during operation of the shake correction mechanism, continuous shooting, and video shooting affects image quality.

In this patent application, Canon discusses a flexible member that joins the sensor platform and the camera body, allowing heat to more efficiently move off the sensor.

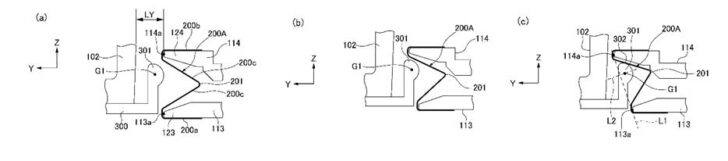

In this rudimentary cross diagram, the camera base (immovable) portion is 113, and the sensor movable platform is 114. The flexible membrane to move heat from the sensor (114) platform is 200. Figure (a) is when the IBIS platform is at a neutral position, and (b) is when it’s at its maximum shifting position. Figure (c) interestingly is when the camera is powered off, and the platform is locked and at rest. I always wondered what that looked like.

This patent application, as Canon states, hopes to improve the heat dissipation and not affect smooth IBIS motion.

Patent Publication No. 2025-176890

This patent application deals with, essentially. Hey, your fancy patents are all cool, but how do we actually put them together? This patent discloses a more optimized design that can be manufactured easily.

The present invention has been made in consideration of these problems, and aims to provide an imaging device that is easy to assemble without impeding the drive controllability of the moving parts while sufficiently cooling the heat from the image sensor.

This patent application deals with how to attach the heat dissipation item between the moving part of the sensor platform and the fixed portion. Interestingly, we see a little on what that conductive strip is made out of as Canon mentions “graphite sheet or the like laminated with a PET sheet and the like.”, which is a pretty common heat spreader material that Canon is using.

Patent Publication No. 2025-176965

This patent application is looking closer at the strip that conducts the heat from the sensor platform to the base, and making it easier to flex. If you consider that an IBIS sensor platform has to move in all directions, you have to appreciate that it's much easier to move lengthwise to the strip, but more resistance when you move the strip's lateral direction. Moving in the lateral direction forces the strip to bend more stiffly, and probably even worse, applies more force to push back against the sensor platform.

How Canon is combating this in this patent is by cutting slits in the heat conductive strip to make the strip easier to flex in the lateral direction.

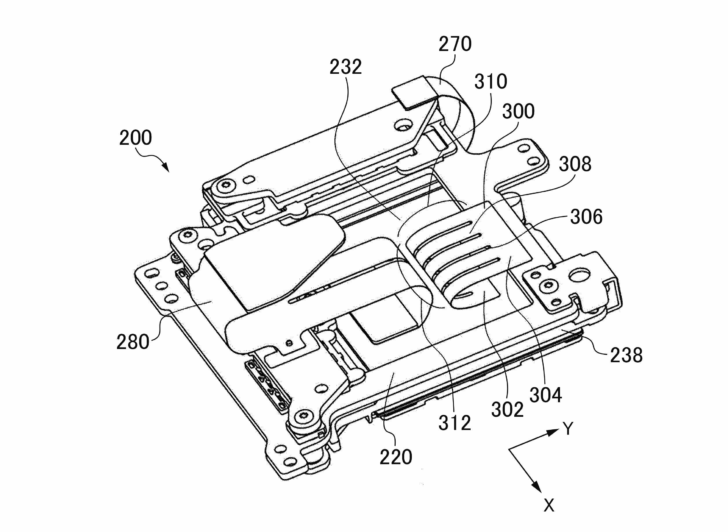

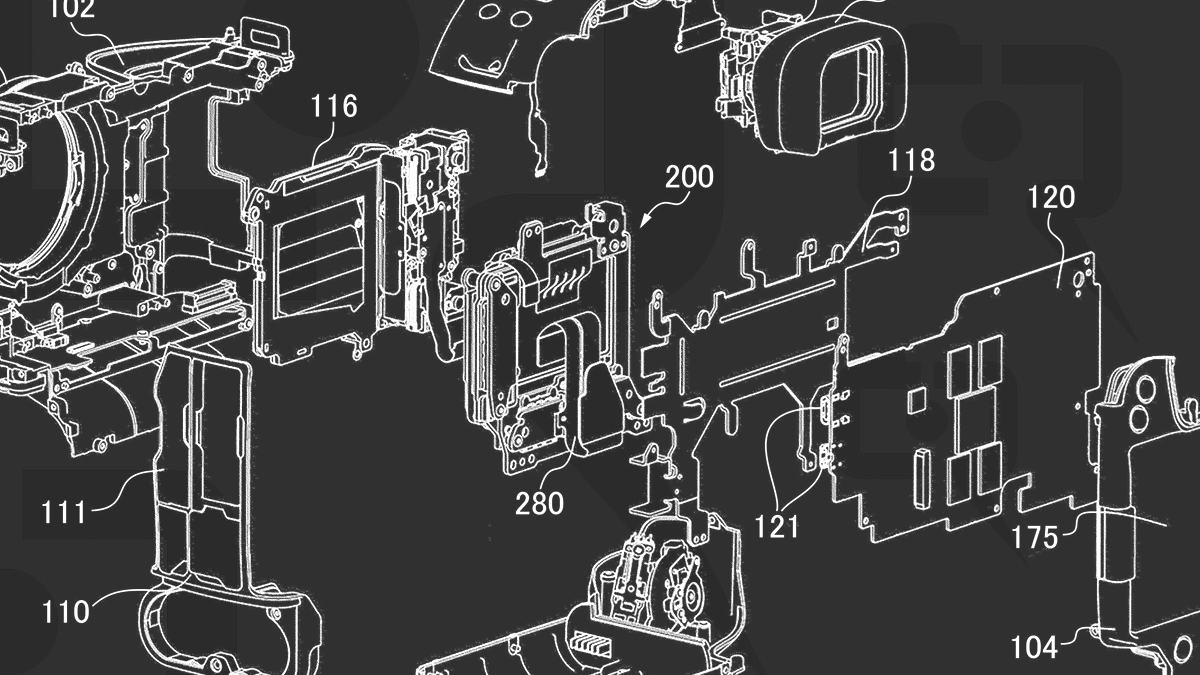

You can easily see this on the above diagram, where the heat conductive strip is 308, and the slits are 306. The same sort of slit seems to be present in the main data flex cable, 280, which is used for data transmission. The smaller 270 flex cable used for data (or perhaps power) does not have a slit, but it's a much smaller flex cable.

Interestingly, the breakout mechanical design of the overall camera shows an integrated vertical grip, such as a 1 or 3 series camera.

I hope they can keep fans or else away from the body by the use of that - at least for stills mainly cams. I'm not interested in long time video, but others are.

The thermal conductivity λ (lambda, GER) or κ (kappa, INT) of copper is ~ 380 W/(m·K), the one of oil 0,15 W/(m·K) and of water 0,5562 W/(m·K).

So many metals are about 600 to 1000 times more effective in thermal conductivity than liquids.

Silver would be the best metal (429), graphene (5300) the highest mentioned in (GER) wiki.

Just with air the heat sink would become too big for most.

I have fully passive cooled PC with an air heat sink filling almost half of the PC housing.

Guess what‘s the connection between CPU and heat sink?

Yes! Massive copper bars!!!

Liquid cooling is cheaper to bridge the (longer) distance between heat source and sink in most other applications.

And for convection (passive or pumped) you‘ll need space. Difficult in a camera housing.

I know what I‘m talking about because I work a lot with power semi conductors like IGBTs - liquid and air cooled.

And when you think about a heat pipe, this is just another physical principle. But not liquid cooling.

That is a heat-transfer device that employs phase transition to transfer heat between two solid bodies.

To original topic was liquid vs. solid body heat transfer.

Of course, all heat losses have to be transferred to air - in the end.

Or do you have your private river in your camera bag?

Again: „heat transfer“ is what I argue about.

But how long could it be inside a camera body?

And how many flexible heat pipes do you know?

Just imagine why the patent mentions metal or graphene/graphite strips.

If they know better what they‘re doing, it seems that my argumentation is closer to their developments and patents than yours.

H2He from getting out. 🤣I just can‘t understand, how much space you think could be in a camera.

If it was, of course heat or liquid pipes would be the much cheaper solution than copper bands or graphene.

Your‘re partly right: just He.

But thank you for correcting me.