When you purchase through links on our site, we may earn an affiliate commission. Here’s how it works. |

It’s easy to take the technology behind autofocus for granted. Time to take a look into the past and see how far we’ve come in the 40-some-odd years of Canon focus motor technology.

Canon Focus Motor Technology in the Distant Past

In the early days of autofocus, Canon’s attempts had an autofocus ranging device and the AF drive motor attached to the lens. The combination then mechanically drove the lens groups.

The Canon Zoom lens, the Canon FD 35-70mm F4 AF was one such example that was the world’s first autofocus zoom lens with an autofocus function. This lens used what Canon called SST (Solid State Triangulation) method to determine the focus distance.

According to Canon Camera Museum, SST was;

The SST method is a system in which information on the photographed object that enters the sensor through two fixed mirrors is converted into an electric signal and distance is measured by a microcomputer, with focusing performed by moving a distance ring with a motor.

In 1987, with the introduction of the EF lens mount and its fully electronic mount, Canon was able to miniaturize the autofocus motor to fit inside the lens housing itself. Canon intended to provide seamless autofocus, but also have it so that each AF motor could be optimized for a particular lens. This would allow for faster autofocus, as well as more precision. This allowed Canon a great deal of flexibility and launched the EOS system we still see today.

This article is going to go through all the various auto focus technologies that Canon has employed over the years with the EOS system, which includes all three branches: Canon EF, Canon EOS-M, and of course, Canon RF.

DC Micro Motor

Canon used a variety of different small micro motor designs through the ages, and even still today, employs that in the “legendary” Canon RF 75-300mm f/3.5-5.6. There are two major types of DC motor drives for Canon lenses, and most of them were in the early days when Canon was figuring out how to do inexpensive auto focus motors.

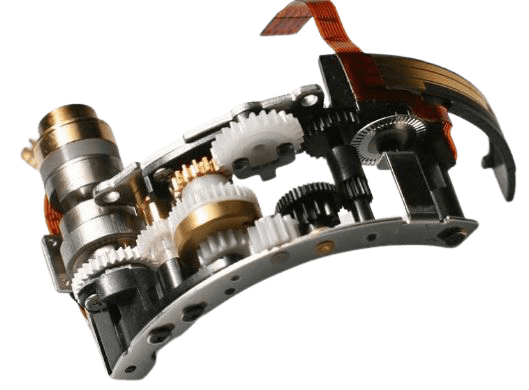

AFD – Arc-Form Drive

The Arc-Form Drive was Canon’s first autofocus motor when the EF mount was introduced in 1987 with the EOS 650. The motor was a stepper motor with the stator shaped in an arc. When the rotor rotated, it shifted the focus group by using a gear train and helical cam to move the focus. The EF 50mm f/1.8, introduced in March 1987, was the first lens with this motor.

The focus operation yielded a very noticeable whine and noise of gears, and it took one to two seconds to obtain focus. Manual operation of the focus was only possible by switching to MF mode since there was no focus override. Other early lenses included the 35-70mm f/3.5-4.5 and the 28-80mm, which employed this system. By 1990, Canon discontinued the AFD, as it moved to the smaller Micro Motor system. The AFD proved to establish the technological base for future autofocus systems in the EF system.

MM – Micro Motor

The Micro Motor was Canon’s standard auto-focus drive for budget EF lenses since 1990. It consisted of a small brushed DC motor, usually 6-10mm wide, being utilized to power a reduction gear train to drive the focus elements through a helical cam, with the EF 35-105mm f/4.5-5.6 being the first lens implementing this technology. The focus operation produced a moderate whir and gear sound, while focusing usually completed its operation in approximately one second. To use manual focusing, the user needed to switch to MF mode.

Common lenses implementing the Micro Motor included the EF 50mm f/1.8 II, EF 75-300mm f/4-5.6 III, and the majority of the kit zooms toward the end of the 2000s. Canon continued using the Micro Motor in some lenses into the 2010s and used a modernized model in the RF 75-300mm f/4-5.6, which was released in 2025.

Ring-Type USM

The ring-type USM motor is the most widely used AF motor in the Canon EF lens range and is primarily used in Canon’s EF mount L series lenses, especially the super telephoto lenses.

Ring-type USM motors are also highly efficient and have low power consumption to maximize the camera battery life. Being ring-shaped, they are ideal for fitting within the lens barrel. Their focusing speed is very controlled, and they are stable across a wide range of temperatures. This reliability makes them suitable for extreme conditions, such as wildlife or sports photography in harsh environments.

They can also deliver a high degree of torque, giving the focus motors the ability to move larger, more complex groups. Ring Type USM motors also allow for full time manual override of the focus, allowing the user the ability to switch between autofocus and manual by simply rotating the lens.

The ring-type USM is actually very simple in operation. It is composed of a rotor and a stator – an elastic body with a piezoelectric ceramic voltage element attached to it. Applying an AC with a resonant frequency around 30kHz to the stator creates vibrations that cause the rotor to rotate continuously. The frequency of 30kHz is in the ultrasonic range, and this is where the USM motors derive their name.

The piezoelectric element generates ultrasonic waves that cause the rotor to create a rotational force that moves the focusing group. Switching the current between two different phases changes the direction of the ultrasonic waves. Consequently, the focus group can be made to move in different directions, giving control over the direction and speed of focus.

Canon still uses ring type USM, but for many lenses it’s been replaced. The Canon RF 85mm f/1.2L USM is one example of Canon’s continued use of a ring type USM focus motor.

Micro USM

Unlike the ring USM, where the stator and rotor are separate parts, in the Micro USM design, the rotor, stator, and drive gear are combined into one unit, roughly half the weight of a ring-type USM motor. While the more powerful ring-type USM is designed to fit in the circular barrel of a lens, making it ideal for use in large professional zoom lenses, the Micro USM motor was created to fit in a wide range of lenses without being restricted to the size of the lens barrel. Micro motors are also cheaper to produce, making them more suitable for use in consumer lenses where cost is an issue.

In principle, the Micro USM works in a similar way to a ring-type USM, with ultrasonic vibrations created by piezoelectric elements. There are four piezoelectric layers, each constructed from two alternating phase piezoelectric elements. These elements are offset from each other in alternating phases by 90°. Applying an AC to only the A-phase causes the stator to vibrate left and right. If current is applied to the B-phase, the stator will rotate forward and backward. When current is applied to both the A-phase and the B-phase, the resulting motion is rotational as the tip of the stator moves, for example, left, back, right, forward, left, back, right, forward. This rotational force is applied to the main drive gear, which in turn is used to drive the gears of the focusing mechanism.

Micro USM was revolutionary for its time, enabling affordable AF in entry-level lenses, but it lacks full-time manual focus in some models and is slower than ring-type USM.

Micro USM II

The Micro USM II motor is essentially a reduced size version of the Micro USM motor. It functions in a very similar way, but the length of the unit has been greatly reduced to allow it to be used in ultra-compact zoom lenses.

The size reduction has been achieved by reconfiguring the rotor and stator so that, instead of the two being aligned in a row, part of the stator is placed inside the rotor. This required the creation of a new format of vibration so that the resonant frequency of the piezoelectric elements was not too high, resulting in insufficient vibrational amplitude.

The outcome is that the Micro USM II is about half the size and half the weight of a Micro USM motor, and yet retains almost the same performance characteristics. Its small size means the Micro USM II is well-suited for use in compact zoom lenses. However, Micro USM and Micro USM II are less common today because of the introduction of more advanced lens motor technologies like Nano USM and STM, which offer better video performance.

STM

The next focusing motor technology developed was a little different. First introduced in 2012 with the EF 40mm f/2.8 STM and the EF-S 18-135mm f/3.5-5.6 IS STM. STM lenses are good for stills, but the auto focus motors are excellent at focusing for video because the STM (stepper) motor produces smooth focusing movement. However, STM may not be the quietest of motors if you are using it in camera microphones.

A stepper motor uses DC (direct current) passing through multiple coils organized into groups. Supplying current to the groups in a sequence rotates the motor one step at a time. More groups enable more precise steps or movements to be made.

When compact size is important, Canon atypically uses gear-type STM technology. This uses helical gears to drive the focus without taking up much space. Larger lenses use a leadscrew type STM system. This is bigger than gear-type STM units, but it’s faster and quieter.

STM is particularly valued in hybrid shooting and is considered inexpensive to use in a lens, which is why you see these motors in Canon’s more economical lenses. Canon is still using these motors for the RF mount, with the Canon RF 16-28mm f/2.8 IS STM, which was announced in January 2025.

While STM is generally an able focus technology, it may not match USM speeds for burst photography.

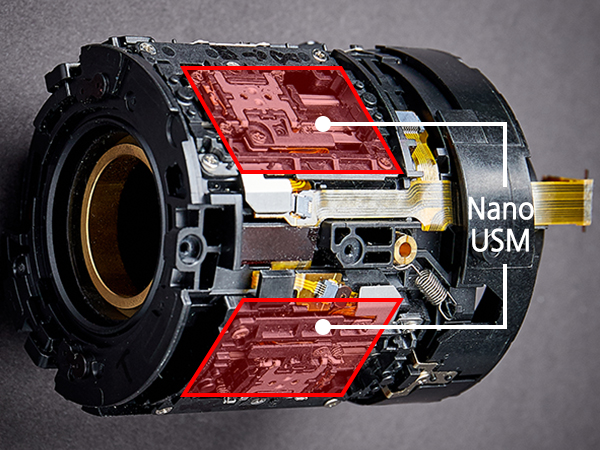

Nano USM

The Nano USM (Ultrasonic Motor) was launched in 2016 with the Canon EF-S 18-135mm f/3.5-5.6 IS USM, and the overall aim was to develop a motor that could provide the speed of focusing that photographers require for stills, but with the smooth, gradual adjustment that is necessary for video.

Similar to the earlier versions of USM motors, Nano USM also utilizes ultrasonic vibration to create movement, but has been miniaturized to be very compact while providing robust autofocus performance.

As in all other Ultrasonic Motor designs, the Nano USM motor has an elastic metal casing, a ceramic voltage element, and a drive unit. By sending current and varying the voltage to the ceramic elements, the Nano USM can create two types of vibrations, giving the motor precise control of the speed and direction of the drive unit. However, in this instance of motion, it is not rotational but linear instead; for lens focus elements, a rack drives the focus element(s) with guide bars that guide and control the forward and backward movement. The result is a very smooth focusing movement, fine control of speed, and near-silent operation.

Nano USM completely closes the gap between the speed of USM and the smoothness of STM, and is especially well suited for EOS R-series cameras with advanced video capabilities.

Dual Nano USM

In line with its name, Dual Nano USM comprises two Nano USM motors driving different lens groups. These groups work together to provide a fast, efficient focusing system, and can also be controlled independently to minimize focus breathing when shooting video.

When the RF 70-200mm f/2.8L IS USM launched in October of 2019, it was the first lens to offer Dual Nano USM technology. It has since become an important feature on pro-level RF telephoto lenses such as the RF 100-300mm f/2.8L IS USM and RF 70-200mm f/4L IS USM, and hybrid video/stills lenses such as the RF 24-105mm f/2.8L IS USM Z.

The dual motor USM also allows for better tracking in Servo AF modes than the STM and single motor Nano USM that came before it.

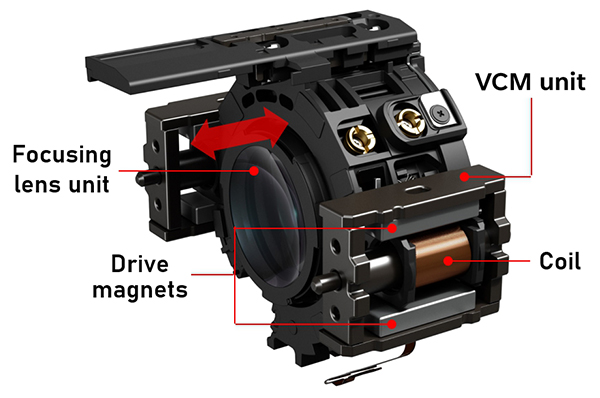

VCM

The newest Canon focus motor technology is the VCM motor. The VCM acronym means Voice Coil Motor. VCM is a powerful and responsive linear drive autofocus motor that has a relatively uncomplicated brushless design. Instead of the focus lens group being moved by ultrasonic vibration energy, it uses a magnetic force for speed and smooth focus adjustments.

The focus unit attaches to a coil of wire located between drive magnets. The voice coil moves back and forth, which adjusts the location of the magnetic field, and will linearly move the coil and focus unit in the lens barrel.

Similar to Nano USM, VCM is fast and precise, fulfilling the requirement for speed and precision for stills, and at the same time, smooth, stable, and near-silent operation for video. A VCM motor also moves heavier focus lens groups that are typical in prime zooms with fast maximum apertures more easily. By 2025, Canon will have expanded the VCM product line to a series of hybrid VCM primes that have a greater emphasis on silent operation for video shooters.

The Canon RF 35mm f/1.4L VCM was the first lens to utilize a VCM (Voice Coils Motor) automated focus motor with a smaller Nano USM (Ultrasonic Motor) focus motor. The focus motors work together with different responsibilities.

The VCM motor moves the larger focusing lens group while the Nano USM moves the floating lens group. The two lens groups can move together or independently, with the floating system used to help suppress focus breathing when shooting for cinema.

A VCM lens will require power from the camera to hold the focus lens group in place. So, if the camera is turned off or if the lens is temporarily detached from the camera, you may hear and see some low-level noise and movement coming from just behind the front element of the lens; nothing to be alarmed about, as this is normal and does not impact the performance of the lens.

The VCM design also helps the camera’s overall battery performance, as it’s more power-efficient.

Closing Thoughts

This article grew a lot larger and a lot more time to read than I had originally envisioned. Some of the motor technology is simply not in existence anymore. Maybe we should be thankful that Canon brought back the R100 of lenses, the Canon RF 75-300mm f4-5.6 so we could marvel about how far we’ve come.

A few things caught me surprise, either that or I forgot about them, but it was a fantastic walk down memory lane. I recall when you could hear the little motor and gears turning while the lens focused, and how different that was to the smooth powerful quiet focus of the ring type USM.

Today we are blessed with quite a few options that Canon uses to provide focus with a higher accuracy and faster focus times than we had in the past.

Reading it was a pleasure.

Let's hope that Canon continues to develop speed and accuracy of focus motors.

Do you mean LENSES not LAPTOPS

whoops

the author had a brain fart. thanks for the catch

"While Canon had advanced autofocus motors like USM, Nikon was still figuring out how to get a motor into a lens."

It would spiril downhill from there 😉

Cost. It's a bummer it doesn't have the latest STM.

Is it really the cost? Or Canon didn't want to make the lens too good because the old 18-135 with nano USM was a similarly "cheap" lens.

Thanks on a really nice article!

By the way, I never imagined the size difference between gear type STM and lead-screw to be that big, that explains a lot!

Chattanooga wedding photographer

1. DC micro motor and micro motor are exactly the same AF motor types, whereas in this summary they are listed as two different concepts (which they are not).

2. Coreless motors have not been used as autofocus motors in Canon lenses. In their Canon EF Works III document, there is one page where coreless DC motors are mentioned. However, after more than 10 years of repairing canon cameras and lenses, I can confirm that coreless DC motors are used by Canon inside of their DSLR bodies to springload the shutter and mirror units, but not inside lenses.

3. The original arc form drive was not a large brushed DC motor as stated above. In fact, the very first arc form drive motor was a stepper motor with a stator shaped in a thin arc to fit inside the lens barrel.

There is a surprisingly detailed and highly accurate source showing all of Canon's autofocus motors here:

ƎXCLUSIVE ARCHITECTURE

Cheers!

See: https://exclusivearchitecture.com/03-technical-articles.html

Personally, I find that even with the amazing AF capabilities in today's R series cameras I still find myself using manual override at rodeos, marshes, wheat fields, etc. I've kept my EF lens stable as a result, and as much as I do appreciate the RF lenses for many factors I simply cannot justify to myself plunking down $1-$6k on anything that does not offer manual focus override without first needing to hit a power button after a moment. Plenty of other toys to get instead. The EF lenses at the L tier are plenty fine for many modern photos, and instant manual is awesome. It really sucked to see RF lens focusing tech partially step back to 1987 when the lenses were first released. If instant manual override returned to the RF line without the need to wake the camera up I would very much seriously consider a lens replacement spree. For now, every so often a Canadian retailer offers stuff like the 50mm f/1.2 for 50% off due to overstock. Unless someone needs the latest and greatest for what they do, it's hard to beat those kinds of deals.

On the other hand, I haven't really turned the ring on many RF lenses this last year. Maybe someone here has and can pleasantly surprise me with a, "hey, check out the XYZ -- it works just like the EF XYZ L USM but sharper, faster, more rainbow-y and also manual MFs with a twist and a dead battery" remark. 😎

But, no doubt, purely from an engineering nerd perspective the advancements are cool!