When you purchase through links on our site, we may earn an affiliate commission. Here's how it works. |

As sensors get more complicated, faster, and also more stacked there is more heat generated from the sensor itself.

As fabrication design rules get smaller, for normal chips that reduces the size of the chip which reduces the resistance to electric current, and usually heat – which is why as design rules get smaller, chips tend to get faster because designers have more heat headroom to play around with. But for a sensor, the size of the chip doesn't change and sensors are very sensitive to heat. As the more heat, the more noise the sensor output has.

So as our sensors get faster and rely on smaller design rules, we don't have the inherent advantages that better lithography systems usually bring to the table to the industry, but we need those better systems to increase the efficiency of the sensor itself. It's all a never-ending juggling act. This is why there are so many Canon (and Sony, Samsung, et all) patents surrounding heat, speed, power, and sensors.

Now we have IBIS. IBIS adds its own problems since it requires the sensor to float because as you jiggle the camera, IBIS jiggles in the opposite directions making the sensor itself seem stable and non-moving. So you can no longer attach the sensor to a heatsink and all your heat problems vanish, because the sensor is on a moving plate, and you still have to move heat away from the sensor.

Not only that but IBIS motors aren't exactly huge, so you have to have as little mass as possible to shift around, the more mass the slower the IBIS motors can move the sensor. The slower the overall IBIS system is, the fewer stops of IBIS you get out of the system. So the plate that the sensor is attached to is as small as possible and therefore can't contribute meaningfully to moving the heat from the sensor.

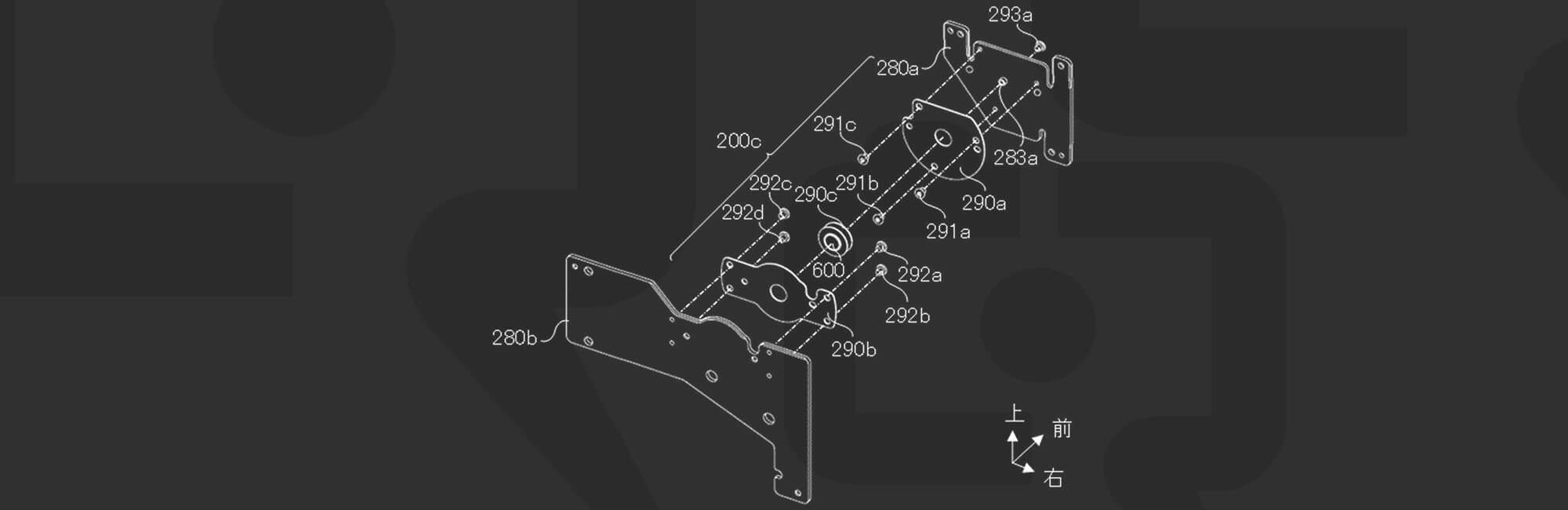

When it comes to heat, generally air is a bad conductor, so relying on the air to transfer heat between two plates, one moving and one fixed, doesn't work extremely well. This is where something like this patent application (2023-154678) comes into play – where Canon is looking at ways of physically connecting the moving plate holding the sensor, and the fixed plate, so heat can be transferred efficiently away from the sensitive areas of the camera.

Canon connects the two plates together with a rubber tube (290c in the diagram above) that is pretty flexible and has injected heat transfer material (600 in the diagram above) inside of the tube. Canon suggests something like Liquid Metal is used inside of the tube, which would give amazing transfer capabilities. As long as it doesn't turn solid, obviously, that would be a problem for IBIS ;) So this would have to stay in liquid form and if it does it would provide a near equivalent of a metal connection between the moving plate and the fixed plate.

There are some flaws with this of course. if that tube breaks somehow (think perhaps you drop your camera) or it simply ages – once it breaks it would spray liquid metal everywhere inside the IBIS/sensor box. That would be bad. Really Really Bad. Like what happened the first time I tried to use Liquid metal on a GPU. Then again, it would give Canon a method of planned obsolescence.

I assume that a copper braid or something similar would have some sort of wearing issue over time, and when you think about it rubber or some other flexible material is most likely more durable than a copper braid, etc. But that's out of my league in terms of knowledge. Someone in the forums will correct me I'm sure ;)

So these types of patent applications are kind of cool (pun clearly intended), as they also cross boundaries and multiple industries, there are a lot of examples of where you need to move heat from a vibrating plate effectively.

Canon shows the example of this being in a R1/R3 styled camera body but it could be implemented anywhere.

Of course, with patent applications, this may never end up as a patent, nor end up in a product, but it shows us details about what Canon is researching.

Even though a lot here are real gearheads, some are not.

I don't see the type of working fluid, and I am not sure how the short length reduces the efficiency.

And as it has to be flexible, this is the most difficult part in adapting a heat pipe for cooling the IBIS.

Quite interesting.

Hopefully this will be restricted to video specific bodies only.

with Canon's IBIS there is two types of corrections - low frequency and high frequency movement. Think low frequency as the slow movement / drift when you are hand holding, and higher frequency as your hand shake after coffee.

low frequency correction this would be ok, but high frequency may be damped a bit - but it really depends on the material they use.

Also the motors are on the fixed plate so that's less of a concern.

I was thingking about this and could only guess - in which cases do you need to remove heat from a vibrating plate?

This is not meant to sound like pandering. It is the right thing to do when dealing with each other.

Thank you!

I can't comment much on it, but I sent the patent application off to the owner of the company that I have another contract with because while it's in a different field we have been grappling around with the same things. So that's one of the few times I was stating something from personal experience 🙂

It would still be better than what we have now so I am all for it.

I do try, feel free to make suggestions.