auto correct is a bugger at times .. but watch out for those chatty capacitors.. nothing you tell them remains a secretIf discreet ones aren't available, can we use the gossipy ones?

Upvote

0

auto correct is a bugger at times .. but watch out for those chatty capacitors.. nothing you tell them remains a secretIf discreet ones aren't available, can we use the gossipy ones?

Do you think that it is worth to keep a full factory of people on the payroll just for a chance that a couple of years later they might be re-trained to do something useful?Probably true, but nonetheless Canon elected to surrender that manufacturing capacity rather than repurpose the plant or retrain the workforce. We don't know why that was the case, but ordinarily companies are loathe to get rid of a skilled workforce unless they are completely confident that they will never again need that workforce, because once you close a plant the workers walk out the door and you generally cannot get them back again.

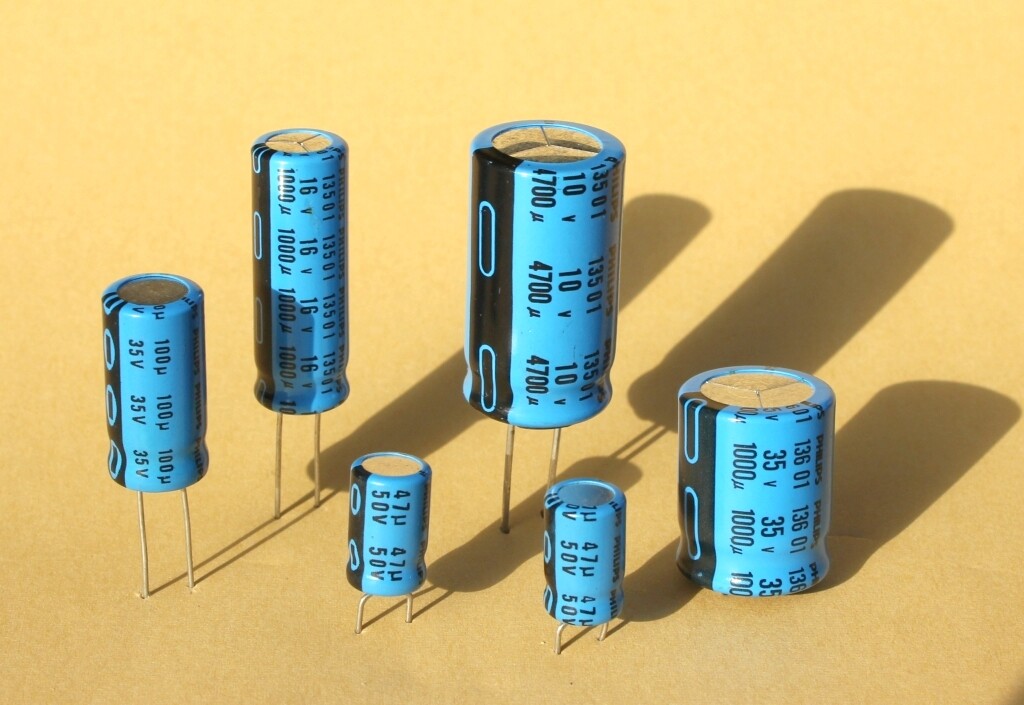

There is apparently a shortage of passive components as well in electronics market:

The New Chip Shortage is Passive Components

If you thought that the chip shortage was bad, then the building shortage of passive components, such as capacitors, resistors, inductors and so on, is going to have you in tears. Due to lockdowns in Malaysia and Indonesia, where most of the well known Japanese aluminium capacitors are made, the...www.techpowerup.com

When I was studying EE, the uni decided to do everything in English instead of Dutch, the discreet/discrete mistake was made very often by everyone, including the professors. I still have to stop and think twice when using that word in writingauto correct is a bugger at times .. but watch out for those chatty capacitors.. nothing you tell them remains a secret

I read an entire novel that used both words, often. And it got them wrong 100% of the time. The author, or his editor, had it backwards in his brain.When I was studying EE, the uni decided to do everything in English instead of Dutch, the discreet/discrete mistake was made very often by everyone, including the professors. I still have to stop and think twice when using that word in writing

"I lived a secret I should have kept to myself but I got drunk one night and I told it" - Bruce Springsteenwatch out for those chatty capacitors.. nothing you tell them remains a secret

Even before the pandemic, Canon had a program to move more camera production to automated/robotic factories in Japan.And yet, Canon just closed a plant in China. They did not repurpose it, they closed it.

Electronical components - the toilet paper of the manufacturing worldAs they are relatively inexpensive, companies are ordering quantities in excess of what they need to make sure that component is on their shelf and won't be a shortage for them in the future.... human nature.

True, but I am referring to the "commoditised" components ie the ones that were cheap and plentiful in the past. There are very expensive components eg sensors that are managed very strategically as the cost/importance is high/high.Electronical components - the toilet paper of the manufacturing world