By Roger Cicala

Published September 10, 2020

Lots and lots of people are talking about Canon R5 heat cut-offs. The discussions range from technical discussions about heat generation, cooling methods, and firmware protocols to strident conspiracy theories.

I only know a little bit about heat:

- Electronics give off heat when they’re working.

- Heat fries chicken, which is good, and fries electronics, which is bad.

- You can get rid of heat by conduction (flowing through nearby materials), convection (circulating through gas or fluids), and radiation (which mostly occurs at high temperatures). We know from the teardown that the R5 is tightly sealed, so we have to figure that convection doesn’t play much of a role.

As a repair and QA oriented person, I hate bricking cameras. So I’m less interested in coaxing the camera into working hotter (see point 2) and more interested in how the heat gets out. When we did the teardown of the R5 we saw some metal heat sink / transfer plates that

would conduct heat away from certain chips, but once the heat sinks get hot, then what happens? That’s what I was interested in.

This is not rocket science, there are people far more qualified than me talking about chip operating temperatures, thermal flow of various substances, firmware cool down cycles, and stuff like that. (There are also people far less qualified than me talking about those things.) I have nothing to add to either of those discussions, and I don’t intend to get into a fracas about it.

This is just some very basic stuff about how heat leaves the camera. Because to my simple mind, getting the heat out of the camera is the end-all, be-all. Tweak heat flow as much as you like inside and maybe you’ll gain a few minutes of this or that. But eventually the heat has to get outside or the camera needs to shut down. I do need to point out that the heat flow with the back off has nothing in common with the heat flow with the back on, so I’m doing this with fully assembled cameras.

First Step

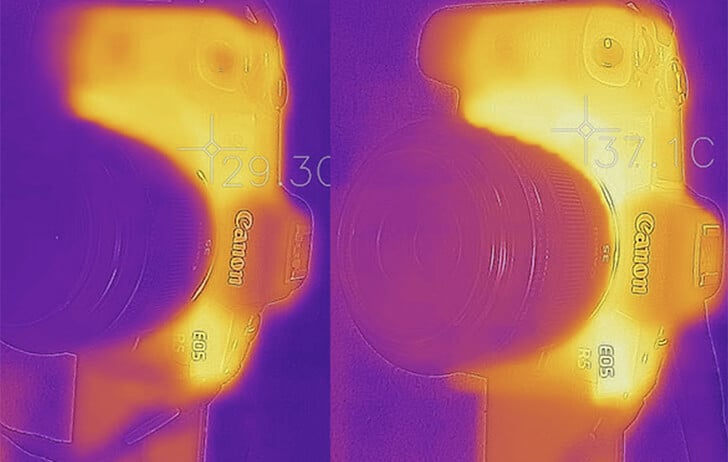

We got an R5 running V1.0 firmware, slapped a CFx card in, put it in 8K mode and ran it to temperature cut-off, using some industrial thermometers to see where heat left the camera.

With lens on, and camera sitting on a table, all covers closed and LCD folded against the camera back but not on we ran it for 18 minutes before getting a temp warning. The hottest part of the camera was the back behind the LCD door (43°C / 109°F), followed by the rear body around the command / set dials and the area of the grip where you rest your thumb (40°C / 104°F). The bottom plate around the tripod socket reached 38°C / 100°F.

The top, front, and sides didn’t warm up much at all, most of the camera was around 30°C.

We redid things with the LCD moved to the open position, away from the camera. This time that area on the back of the camera was a bit cooler, 39.5°C / 103°F but nothing else changed

much. So a few takeaways: First, leaving the LCD open let the camera radiate heat a bit better,

which is pretty logical, but not better enough to prolong recording time. (We did use the same CFx card for both runs.)

Next, we waited until the camera cooled enough to record again and restarted. The only interesting part of this was the second shut down occurred at a degree or two lower external temp than the first. Is this because of the delay getting residual heat out of the insides? The inside should be hotter than the outside, because thermodynamics, but I couldn’t measure how great that difference was.

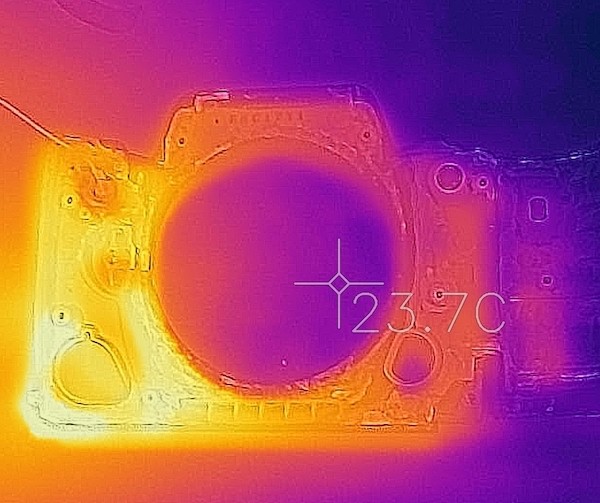

At this point, we decided that the thermometers we were using were reading from a 1cm² area, which was kind of a blunt tool. So I got a little FLIR IR camera, spent some time checking it’s readings against both of the thermometers we used and decided it was just as accurate and gave us a lot more information. Plus cool pictures that are more fun to look at than rows of tables.

The Chassis and Shell

The chassis and shell of most cameras has been developed for years to to be strong and light (most manufacturers use similar material). I’ve never thought they conducted heat well, but I didn’t know for sure.

So we took a shell off to test this a bit. Just simple stuff; I used a narrow gauge heat gun to heat the shell and see what happened.

First we heated the inside of the shell with rubber intact, and tested the temperature on the other side. We found that the shell is indeed not a good heat conductor. Heating the inside up to 180° F

/ 82°C the outside got up to 160° F, but with several seconds delay. With the rubber grip applied the difference was, as you would expect, a bit longer and the outside reached about 150°.

Then we heated one corner of the shell looked to see how far the heat spread. We knew heat crossed the 2mm thickness of the shell slowly, so I figured it wouldn’t conduct heat to other parts of the shell very well. For once, I figured right.

We had to go back to our industrial thermometers for readings here, the spectrum was more than our little camera could handle. But I’ve got that bottom corner heated up to 180° F, the rest of the shell isn’t very hot at all.

I kept the corner hot for a few minutes and we did get some local spread, but I’m not sure if some of that was leakage from my heat gun. It’s very clear, though that the shell material doesn’t spread heat especially well. If this was aluminum or copper the whole shell would have heated up. Obviously, it does pass heat out of the camera to some degree, but it sure doesn’t act as a heat sink or anything.

Continue reading at Lensrentals.com

Lensrental R5 heat emission investigation

I'm curious to see how long it would take to cool down the camera completely to where it started after it heats us to the point of shutting down.

Also what temp it changes to when it's able to record again.

But to be honest, given these findings I would not want an R5, if I were to use it for any of the extreme heat producing features (4k HQ, 8k, super fast burst). A camera that builds up and stores heat like that does not inspire confidence in its longevity, especially with moving parts like IBIS and shutter. Obviously I believe that this camera will do well and tested appropriately, but this is just an irrational feeling of mine. Anyway, it is beyond my financial reach and from all I have it's one of the best photographic tools on the marker as of now. So anyone who has it will enjoy it to the fullest I am sure.

Now give me some sweet deals on the R + 24-105 L. :D

I would have thought so, too.

I would be surprised if the moving parts were more likely to suffer negative side effects from heating up than the electronics. But Canon knows the specs that their components can handle. Which is why they restrict operation of the camera to stay within these limits. Keep in mind that even a company like Apple, who have quite a reputation for reliability, are running their Intel chips at the very edge of what's acceptable under load (peaks of 99° C and sustained at 90° for iMac and MacBook Pro, for example). Those products are the same as the R5, equipped with more computational power than can be removed from the device (because of weather sealing in the R5 and not wanting to use proper fans that introduce noise and bulk in the Macs).

To test the tripod mounting plate possibilities, find a scrap metal yard that has some extruded aluminium (or copper) that someone didn't need and screw the camera onto that.

That sort of design would open them up to more complex third party solutions as well. Of course, to achieve this they would actually have to use temperature sensors inside the camera instead of just a timer to determine when it should shut down.

It sure has felt that long!

But it would be a good idea to really control the peltier to cool things down the right amount - not too much to avoid condensation inside the camera and to steep thermal gradients.

I do believe that too, it's just an irrational feeling on my end. It also helps making happy that I can only, if at all, afford an EOS R. haha

This video shows clearly that the camera shuts down when it reaches fairly high but safe temperatures (and before these temperatures get too high) to protect itself and the person operating it which makes sense.

This is obviously not suitable to film for hours but they make cinema cameras for that.

But people who make you tube videos expect this to work like a cinema camera so they can make 8K and 4K120 videos for hours on end so their fans can watch them on smartphones at 720p and they’re whining about Canon not fulfilling their delusional fantasies

p.s. I don’t understand why Canon hasn’t removed the 30 minute recording limit though as the European sales tax on video cameras has been revoked

Water transfers heat very quickly

Or you could just accept the camera for what it is : worlds best stills camera which can also shoot short clips of high resolution video

Well in future perhaps we can point the clowns over here and maybe it will shut them up.

Nah, probably not.

I'm just saying this could be corrected in future versions of this camera, say a mark II version. I'm simply discussing ways that could bleed off heat without compromising sealing. Just making more of the camera metal wouldn't necessarily work as more metal in the body shell would have to account for more contraction/expansion which makes sealing more difficult. However a smaller spot dedicated for heat might offer a easier place to channel that heat to, and could allow for third party cooling passive or active solutions, or other external solutions as I proposed a they would not entail having a fan within the camera itself.