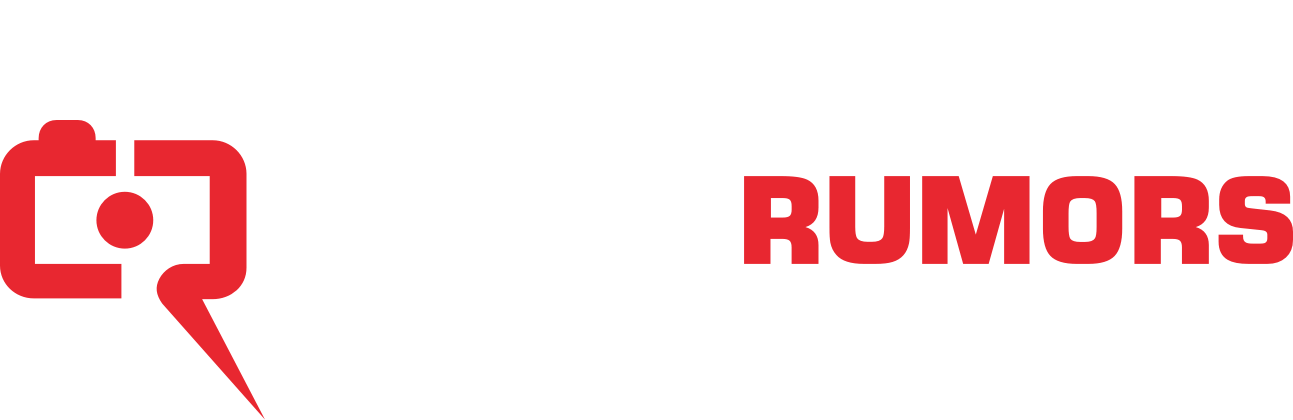

A patent showing a new type of lens cap/lens hood that stays affixed to the lens has appeared from Canon as been uncovered by Canon News.

This lens cap design stays attached to the lens and also doubles as a lens hood for convenience.

This design may have some usability concerns with dedicated lens hoods and filters, but could still be the right solution for some people.

From Japan Patent Application 2019-113645:

The present invention works as a lens hood function at the time of shooting and as a lens protection function at the time of non-shooting, thus eliminating the need for lens cap attachment / removal and barrier opening / closing operations. .

|

When you purchase through links on our site, we may earn an affiliate commission. Here's how it works. |