As an added note, the type of Fluorite Glass that Canon (and others!) use for their lenses tends to have a refractive index of about 1.43 with about 90% light transmission (plus or minus 1-to-2%) AND low-dispersion while Optical grade Acrylic is typically 1.49 with a transmissibility of over 92%.

Canon ALSO TENDS to use very high end coatings to reduce glare, reflections and to cut off IR (Infrared) and UV (Ultraviolet) bands which can create chromatic aberrations even if the lens element itself is perfect ground to high-precision concavity/convexity measurements for proper and/or the desired refraction paths.

With acrylic, the polymer nature of it allows for specific chemistries AND grinding/pressing to specific measurements that allow for ULTRA-HIGH-PRECISION light path management which ensure almost no chromatic aberration, no coma, no spherical aberration, no distortion, no astigmatism, etc. When properly "doped" with proprietary additives, it ALSO HAS a low co-efficient of expansion versus other polymers such as Polycarbonate so we can KEEP those precision calculated light paths perfect throughout the day and night in any temperature and weather.

In terms of light-gathering ability, the REASON we can offer a T1.0 lens is because we simulate using advanced ray-tracing techniques and simulation of the molecular-chemistry-based characteristics of light absorption within a polymer lens. This means we use a supercomputer to simulate on a grid from 65,536 pixels by 65,536 pixels imposed on EVERY lens element in our lens designs what individual beams of monochromatic Red, Green, Blue, IR and UV light do when traveling through a lens assembly from front to back and then on towards the imaging chip of the camera itself.

We answer the question of which pixel coordinates on each grid does each beam of light pass through on the path down the entire lens barrel. We examine and simulate HOW light scatters, refracts, diffracts and converges on every single grid point to ensure OPTIMAL light path management under a wide range of operating temperatures ranges and wide range of all-weather and non-optimal atmospheric conditions!

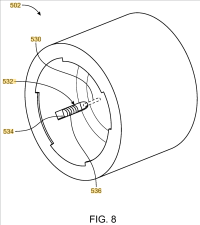

This lets us create a FULLY-AUTOMATED MANUFACTURING SYSTEM that has ultra-precision measurements and premium tolerances ensuring that each light beam from corner-to-corner for each lens we build ends up on the desired pixel of each imager chip we build and install in each camera.

The light gathering power for each frequency and amplitude of RGB/IR/UV light ray through each pixel-grid-coordinate can be FULLY MODELLED and corrected-for via precision grinding, stamping, polishing steps and via hardware-and-software-based RGB value auto-correction.

Since we can build a 50mm to 1200 mm Super-zoom at T1.7 to T4.8, it means the flexibility and pure light-gathering power is UNMATCHED in the lens making industry. AND we can do it at a price point that is ALSO UNMATCHED because the molecular chemistry and manufacturing steps required for polymer lenses is MUCH FASTER than trying to grow fused glass lens elements or grinding and polishing high-end glass lens elements to specific measurements! We can high-pressure STAMP-OUT a pre-shaped Acrylic Lens Blank in mere seconds and then micro-grind and super-polish lens elements using FAST mechanical and chemical systems in mere minutes rather than hours and days!

We have ALSO MUCH SIMPLIFIED lens barrel construction using MUCH OLDER prime and zoom lens designs but updating them for modern ruggedized all-weather usage. In this case, we have found that the older, now-patent-free German and Japanese lens designs TRULY ARE THE BEST MEANS to get a PREMIUM QUALITY still photo and cinematography/videography prime and zoom lens! Vastly simplified but very rugged motor designs, much simplified older but ruggedized lens stabilization systems and much-beefier-and-more-rugged lens-locking mechanisms let us give you PREMIUM LENSES WITHOUT THE EXTREMELY HIGH Zeiss Master Prime or Leica Summilux-C Prime price points!

We have no problem giving substantial credit and accolades to the MASTER LENS DESIGNERS OF OLD FROM GERMANY AND JAPAN who truly made CLASSIC LENSES that just worked and worked forever with very few issues. We have dedicated ourselves to BRINGING BACK those classic workhorse lens designs of old BUT UPDATING THEM for modern usage patterns!

Our modernized lenses are bigger lenses than an average Canon, Zeiss or Leica lens BUT they sure are much more ruggedized and able to go ANYWHERE IN ANY WEATHER !!!

Using an analogy, we are giving you a huge V8 engine in a Ford F450 Superduty Heavy Duty Truck body that's big, bulky and rugged BUT it also pulls 35,000 lbs so it means MUCH LIKE THAT SORT OF BIG ENGINED TRUCK, we just happen pull a LOT of modern super-sharp and colour-neutral optical power out of an older but beefier set of classic prime and zoom lens designs!

V