New York — A new startup – Colorado Tripod Company – today announced the world’s first titanium tripod and ballhead. “Although the process of extracting titanium from its ore is costly, designers consider it valuable enough for specialty applications such as aerospace, where its combination of strength-to-weight and corrosion resistance is unrivalled.” says mechanical engineer Nikki Gantos.

Learn more about the Colorado Tripod Company on Kickstarter

The product line features a number of improvements including a titanium hollowball that the tripod company claims will reduce the ball weight by 52%. Other highlights include ballheads with a maximized range of motion and tripods built to streamline parts and materials.

Range of Motion Dramatically Increased.

One of the new products, the Aspen ballhead, has a design which increases the range of motion far beyond traditional ballheads. The new startup says this enhances the user experience by allowing the photographer to capture compositions easier and more quickly than traditional ballheads which can often require tripod leg adjustments. And by increasing range of motion, L-brackets are no longer a required accessory for rapidly framing vertical compositions, reducing additional weight and cost.

The design process incorporated feedback from prototypes sent to professional photographers.

During the development process Colorado Tripod Co. sent numerous prototypes to professional photographers to incorporate their feedback into the iterative design process. The result is a ballhead with a large 48mm ball diameter, 25lb locking force and an incredibly low weight of 16oz.

“Beautiful piece of equipment both in design and engineering. I like the ‘cut-outs’ (for lack of a better term) that reduce weight but take nothing away from sturdiness.” said Greg Vaughn, a professional photographer who had a chance to test one of the prototypes.

Reimagining the Traditional Ballhead.

The new startup also announced a second ballhead called the Highline. “For decades tripod companies have optimized ballheads for right-handed use relative to the drop location for vertical compositions. Since cameras are right-handed, why don't ballheads optimize the ballhead tension knob for the left hand? This was one of the many questions related to user experience we began asking during design and engineering of the Highline ballhead.” says Gantos.

Learn more about the Colorado Tripod Company on Kickstarter

The Highline ballhead has an all-new patent-pending enlarged opening design which increases the range of motion so the photographer doesn't have to adjust the tripod legs as frequently. To achieve a $99 target retail price, Colorado Tripod Co. engineers analyzed over 25 ballheads, which include all the best sellers on the market today, as well as vintage ballheads dating back to the 1920s. The goal was to make a product that was easy to repair and less complex to manufacture. What their engineers discovered allowed them to reduce the internal part quantity by 50%.

Through numerous strength tests of all 25 ballheads, Colorado Tripod Co. redesigned the locking mechanisms that translate into load capacity. The changes, in turn, increased locking force to 54lbs – more than double industry leaders such as Manfrotto and Gitzo – while still maintaining a small size and weight.

The World’s First Titanium Hollowball.

Due to the strength achieved by machining the Highline ballhead from a solid block of titanium, Colorado Tripod Co. was able to produce an ultralight, patent-pending hollowball which they claim reduces the ball weight by 52%. “Despite how difficult and time consuming it is to machine with titanium compared to aluminum, titanium's strength-to-weight and corrosion resistance are unmatched, making it the best metal for ultralight outdoor photography products. We have constructed our Highline ballhead entirely from titanium to maximize these properties – from hollowball to shell to the internal mechanisms, even down to the screws,” says Gantos.

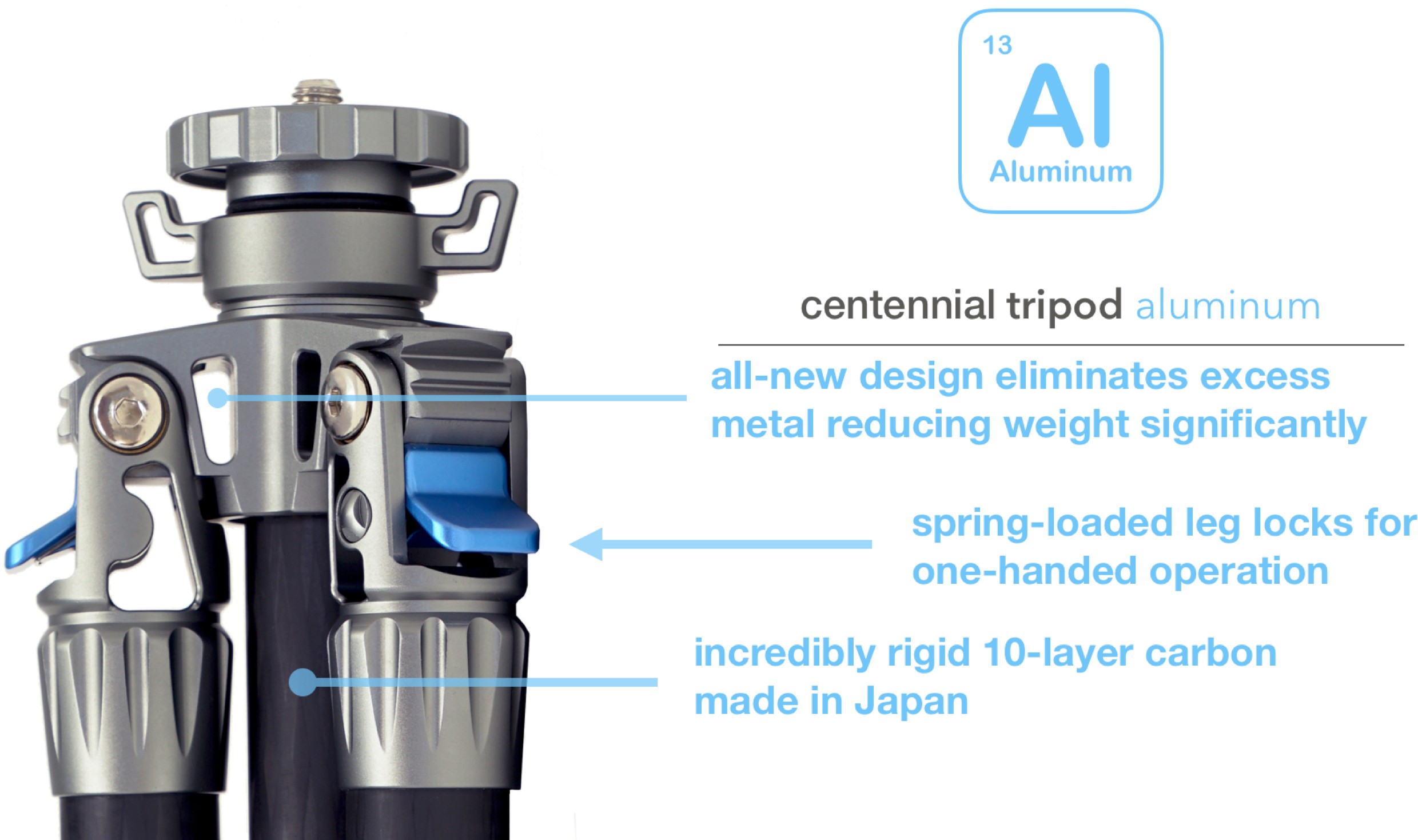

A Unique Approach to Tripod Design.

Magnesium casting has long been the favorite process for mass production of industry leaders such as Manfrotto, Gitzo, Induro, Vanguard and many others. Compared to CNC machining, cast molding is significantly less expensive and the manufacturing time is greatly reduced.

Learn more about the Colorado Tripod Company on Kickstarter

“But by CNC machining products from solid blocks of metal, we're able to get stronger and more precise parts with incredibly durable and beautiful finishes not possible with cast molding. And by CNC machining our all-new Centennial design from a solid block of aluminium or titanium, we're able to create a product which would be structurally impossible with casting,” says Gantos. “By cutting material in areas that would typically be required on a cast mold, we've been able to reduce weight without sacrificing any stability.”

Pricing and Availability.

The startup launched the products on Kickstarter with big savings for a limited time off the retail price “to see if there is a demand for ultralight tripod products with a greater range of motion.” says Gantos. “If successful, B&H, Adorama and retail stores (including Amazon) will begin selling the new tripod and ballhead products after manufacturing completes in March.”

Product Pricing

- Highline Ballhead Aluminum: $99 / $79 on Kickstarter

- Highline Ballhead Titanium: $499 / $399 on Kickstarter

- Aspen Ballhead Aluminum: $199 / $179 on Kickstarter

- Centennial Tripod Aluminum: $299 / $249 on Kickstarter

- Centennial Tripod Titanium: $899 / $799 on Kickstarter

Tripod & Ballhead Set Pricing

- Highline Al Ballhead + Centennial Aluminum Tripod Set: $398 / $298 on Kickstarter

- Aspen Ballhead + Centennial Aluminum Tripod Set: $498 / $398 on Kickstarter

- Highline Ti Ballhead + Centennial Titanium Tripod Set: $1398 / $1098 on Kickstarter

Learn more about the Colorado Tripod Company on Kickstarter

Magnesium casting has long been the favorite process for mass production of industry leaders such as Manfrotto, Gitzo, Induro, Vanguard and many others. Compared to CNC machining, cast molding is significantly less expensive and the manufacturing time is greatly reduced."

Far from unique. Every start-up that needs to render structural parts in metal but can't afford the tooling for casting or forging (both have high start-up costs, but low material waste and per-unit costs) resorts to CNC machining (low-to-no start-up costs, i.e. can be easily outsourced, and high material waste and per-unit costs).

https://diecasting.com/blog/2018/06/05/die-casting-vs-machining/

It's like boasting about being "hand-made" when in-reality you simply don't have enough capital to mass-produce.

It's also true that CNC machining sound "sexier" than vulgar casting, yet pressure die-castings can nowadays attain an incredibly high precision.

As you wrote, tooling costs are much too high for small companies or start-ups, but no reason to discredit castings!

You could design a critically damped structure with any of the materials.

Bought my daughter a Dean Scout and Lightspeed gave her a road frame back when she was racing. Gotta love Ti. She did crash the mountain bike a lot, but never had any denting problems. Here it is 20 years later and the Ti frames are incapable of rusting like steel or pitting like aluminum. Fantastic stuff. I think a Ti tripod is more for "status" than anything else. However, carbon fiber can get gouged. I'll be keeping my carbon fiber tripod. :)

When I changed to carbon from aluminum, vibration reduced from 6-7 to 2 seconds. Are Gitzo and RRS legs designed for better dampening than Manfrotto, is it the carbon or both?

Indeterminate; not enough information is given.

Chances are the RSS legs are stiffer, and thus have a higher natural frequency, so maybe it’s vibrating but you don’t notice. It would be interesting to instrument various tripods with accelerometers and quantify damping relative to various inputs.

Of course it is up to the customer to decide if that is worth north 1k bucks with tripod and ballhead made out of Ti.