You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Teardown: The Canon EOS R5 gets an autopsy

- Thread starter Canon Rumors

- Start date

Bizarre analogy but funnyEdit: I forgot to mention I would rather bathe my cat while naked then read anything on EOSHD...

Upvote

0

This is THE post I've been waiting for!I can't get through a single thing from EOSHD. That guy is so full of ego and states his opinions as facts without sufficient logic or substantiation. Having a following doesn't make someone right. He typically makes emotional stabs at anyone in his forum who dares to disagree with him, however civilly they are discussing a matter.

As for making assumptions on the teardown and materials of R5? Are any of these talking heads or random people with angry opinions (because they can't buy a cinema camera for $4000) actually electronics engineers or have ever done a thermal analysis? If so, I expect more rigor than they are presenting. I have plenty of knowledge in this area and will leave it at that, but I'm not here making speculations despite my knowledge. Unless I know the power dissipation of all components in all modes, the thermal resistivity in each material, and run a 3D thermal analysis myself, I know better than to guess. There is no point acting like we know what the problem fully is. Sure, testing might yield some results, but people acting like Canon are idiots are being unfair....The assumption that armchair engineering is better than a dedicated team that cares about the product at Canon is ridiculous.

Regarding calling for legal action because people cannot read a spec sheet? Good luck in court with that weak argument and your 'righteous' anger. Pretty hard to make a legal case when you were told prior to purchase there are limits with the camera video modes, and that other camera activity could also downgrade the recording time.

Yes, if all you care about is a dedicated video camera that does all this incredible footage in a tiny MILC body, it is not for you, grab a Sony and enjoy life and 12MP stills. You are also unrealistic for thinking a full frame high MP camera with IBIS in a weather sealed body would NOT have some heat issues doing all that. As the mirrorless 5D5 this camera delivers incredible stills and light duty video. I'm having a blast with it and already producing great images.

Certain people always focus on the negative and are always victims no matter how much logic is applied.

Thank you!

Upvote

0

Thermal pads on RAM but no thermal pad on CPU. Generally, CPU run much hotter than RAM.Reasonable criticism? For a totally unreasonable allegation of conspiracy? Where does one start?

Troll.

Also the way they place thermal pads of RAM partly cover CPU's surface is either carelessly or conspiracy.

I'm doing camera and phone repair, something look quite obvious to me, might not be so obvious to other, I guess.

Upvote

0

no thermal pads on CPU: there is a PCB board directly above the CPU. are you suggesting to have thermal pad installed on top of the CPU and transfer the heat to the PCB above? not a good idea.. in my opinion, it would make sense to have thermal pad installed from the opposite side of the CPU board and transfer heat to the chassis..Thermal pads on RAM but no thermal pad on CPU. Generally, CPU run much hotter than RAM.

Also the way they place thermal pads of RAM partly cover CPU's surface is either carelessly or conspiracy.

I'm doing camera and phone repair, something look quite obvious to me, might not be so obvious to other, I guess.

I

Upvote

0

How expensive is the LI-9000 (let's ignore the costs to implement it into a body)? And how big would the tile need to be at 5mm thickness?Right On Here! Since we actually DID DESIGN and BUILD a three million dollar 131,072 by 131,072 pixel CMOS image sensor on an ultra large 400mm Si-substrate glued to a large plate of micro-channel embedded Al2O3 ceramic which melts at about 2072 degrees celcius ... AND a 50.3 megapixel Global Shutter IP69/Milspec 810-G rated combined Stills/video system.... I think I can DEFINITELY chime in on HOW Canon could fix this!

First thing they need to add is a long term heat sink that is of enough mass and such a poor conductor of heat that it can ABSORB heat continuously and dissipate it ever SLOOOOOLY for many hours (12 hours+)!

You need basically an interior shell of molded LI-900 Silica Tile within the back of the camera about 5mm thick that wraps around and/or encases only the rear of the camera and into the battery and card slot compartments.

A series of thermal transfer plates made of solid copper that are attached with a long-lasting thermal paste from the CPU(s), from the memory card slots and battery compartments will move heat via solid copper metal tubing that is embedded into the LI-900 silica.

It quite quickly transfer thermal energy into the ceramic tile very much in the same manner as the old U.S. Space Shuttle Heat Shield tiles did when that spacecraft re-entered the atmosphere and superheated the tiles to 1650 Celcius. So much heat was ABSORBED yet you could STILL TOUCH the corners of the tiles with your bare fingers!

Just based upon some observations and math from the OP's teardown, we could use LI-900 tile at 5mm thick to absorb about 12 hours MINIMUM worth of heat (i.e. 145,000 joules for a typical 40 watt ARM/Canon DIGIC cpu per hour is my estimate) if you use a heat sink mass that is 5mm thick like LI-900 Silica glass ceramic within a body the size of the Canon R5 which will STILL allow normal handheld operation for that entire period.

NO OTHER passive or active cooling would be needed!

The silica radiates heat so slowly that a simple external metal tube that goes from the interior of the LI-900 tile to a 2 cm square metal plate on the bottom of the camera could cool down the camera enough after the 12 hours of solid operation that it would be ready for use the next morning. To get EXTRA heat sink ability just use a thicker tile at up to 10mm thick.

At 0.144 grams per cubic cm, it is so light you can embed lots of it into the NEW R5 or R1 cameras!

Use a thicker ceramic plate at say 10 mm thick and we could get a full 24 hours worth of operation at full DCI 8k 30 fps or 120 fps DCI 4k recording on the Canon R5.

LI-900 Silica tile -- Try it Canon!

V

Then you would need to factor in multiple copper pipes (CFE, Digic, Memory, Not sure whether you can for the sensor given IBIS), so at least 3 copper pipes)?

Plus the CFE generates a lot of heat from what others are saying as I don't think it has any other choice but to heat up it's metal casing.

And out of curiousity, if the Silica tile is exposed to the outside, does it dissipate any quicker? If Canon used it in the bottom of the body, would that help dissipate quicker? If I understood you correctly, it wouldn't be hot to the touch, but would increase the bottom of the case by 5mm? Is the tile sturdy in all other respects?

Finally, your solution is perhaps a little high end. The R5 is not intended to be a 8k video workhorse, I think many would be happy to shoot stills, shoot HQ video, shoot stills and the only limit is the max record times. I'd be fine with that. Is there anything you know which may not be as costly as the ceramic tiles?

Upvote

0

Then it's hard to explain why thermal pads on RAM then? And it's still better to have the heat on PCB than on CPU. The solder lead can withstand at least 200 Celsius and up to 350 depend on the type they use. Components like resistors, coils, capacitor could withstand the heat better than CPU.no thermal pads on CPU: there is a PCB board directly above the CPU. are you suggesting to have thermal pad installed on top of the CPU and transfer the heat to the PCB above? not a good idea.. in my opinion, it would make sense to have thermal pad installed from the opposite side of the CPU board and transfer heat to the chassis..

I

But you got a good point, there is a bigger chasis underneath that CPU, maybe it's better to dissipate the heat to there. But the right way to do so is flipping the CPU board so the top of CPU touch that bigger chasis. Because disspate thru the PCB itself is not so effective.

Upvote

0

It may work. however, I am under an impression that the biggest issue here is the CFE cards are running very hot.Then it's hard to explain why thermal pads on RAM then? And it's still better to have the heat on PCB than on CPU. The solder lead can withstand at least 200 Celsius and up to 350 depend on the type they use. Components like resistors, coils, capacitor could withstand the heat better than CPU.

But you got a good point, there is a bigger chasis underneath that CPU, maybe it's better to dissipate the heat to there. But the right way to do so is flipping the CPU board so the top of CPU touch that bigger chasis. Because disspate thru the PCB itself is not so effective.

Upvote

0

Absolutely!I’m fine with the cutoffs. This isn’t a cinema body. It isn’t an A-Cam or B-Cam body. This is for specialty situations, or for those of us that mix a little video with photo work. I prefer Canon protecting the longevity and reliability of the camera and sensor. I like knowing that this will be the same on every job.

Upvote

0

Your cat wears clothes? I thought they always bathed naked.I forgot to mention I would rather bathe my cat while naked then read anything on EOSHD...

Upvote

0

they aren't thermal pads. Why the blazes would you have thermal pads when a daughter card is sitting on top of them? What do you want to do? cook the daughter card?Thermal pads on RAM but no thermal pad on CPU. Generally, CPU run much hotter than RAM.

Also the way they place thermal pads of RAM partly cover CPU's surface is either carelessly or conspiracy.

I'm doing camera and phone repair, something look quite obvious to me, might not be so obvious to other, I guess.

I updated our article...

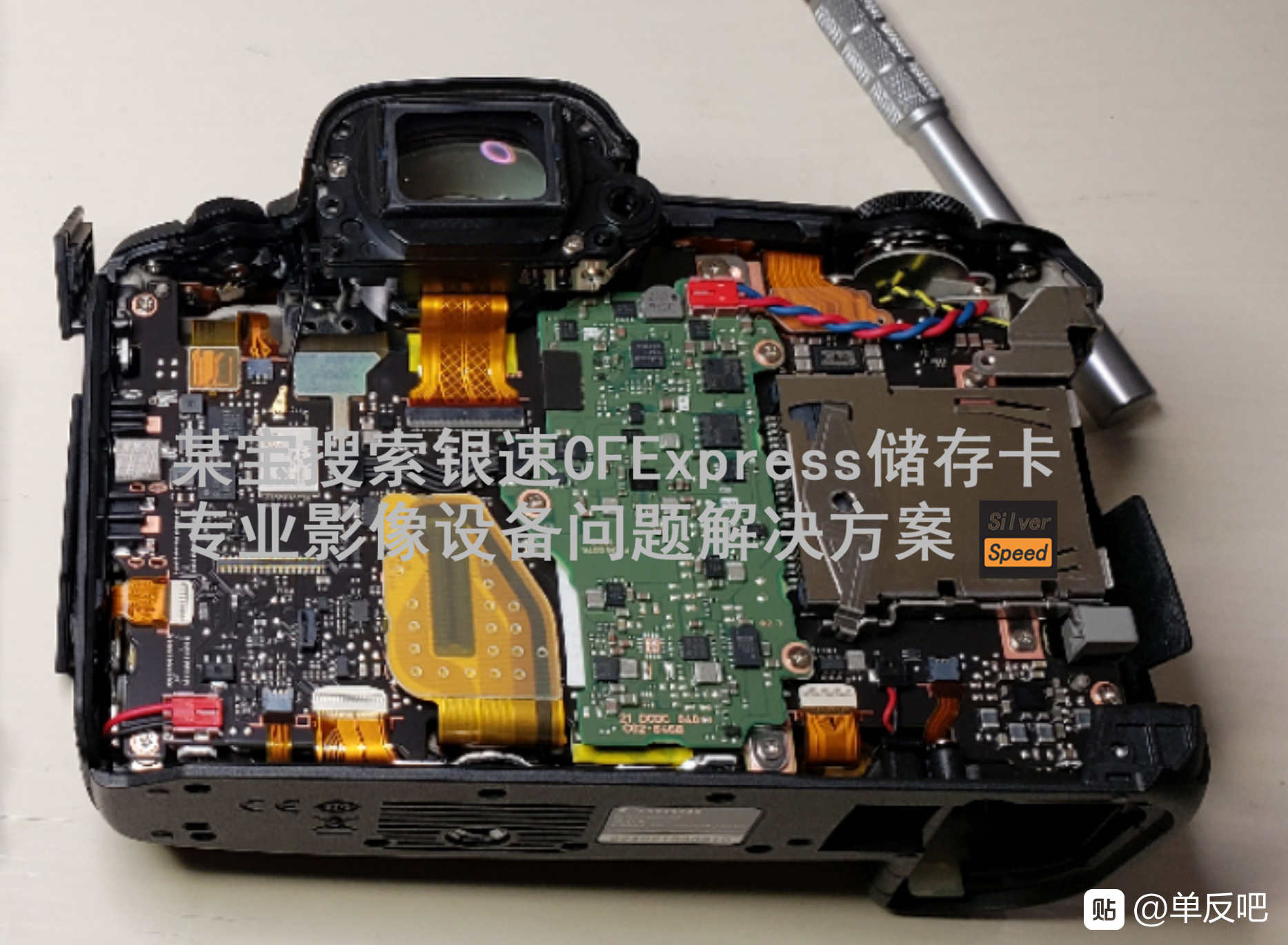

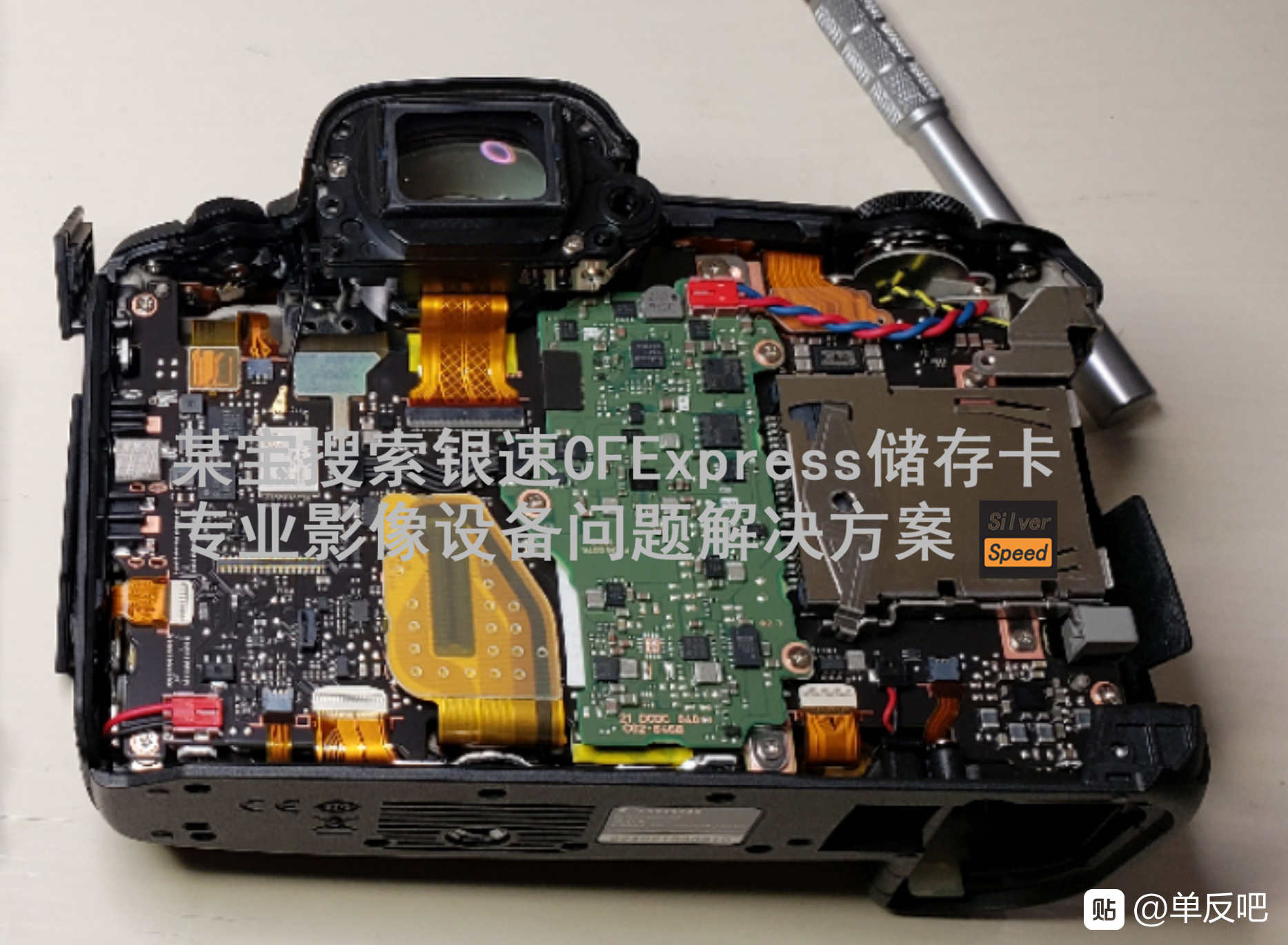

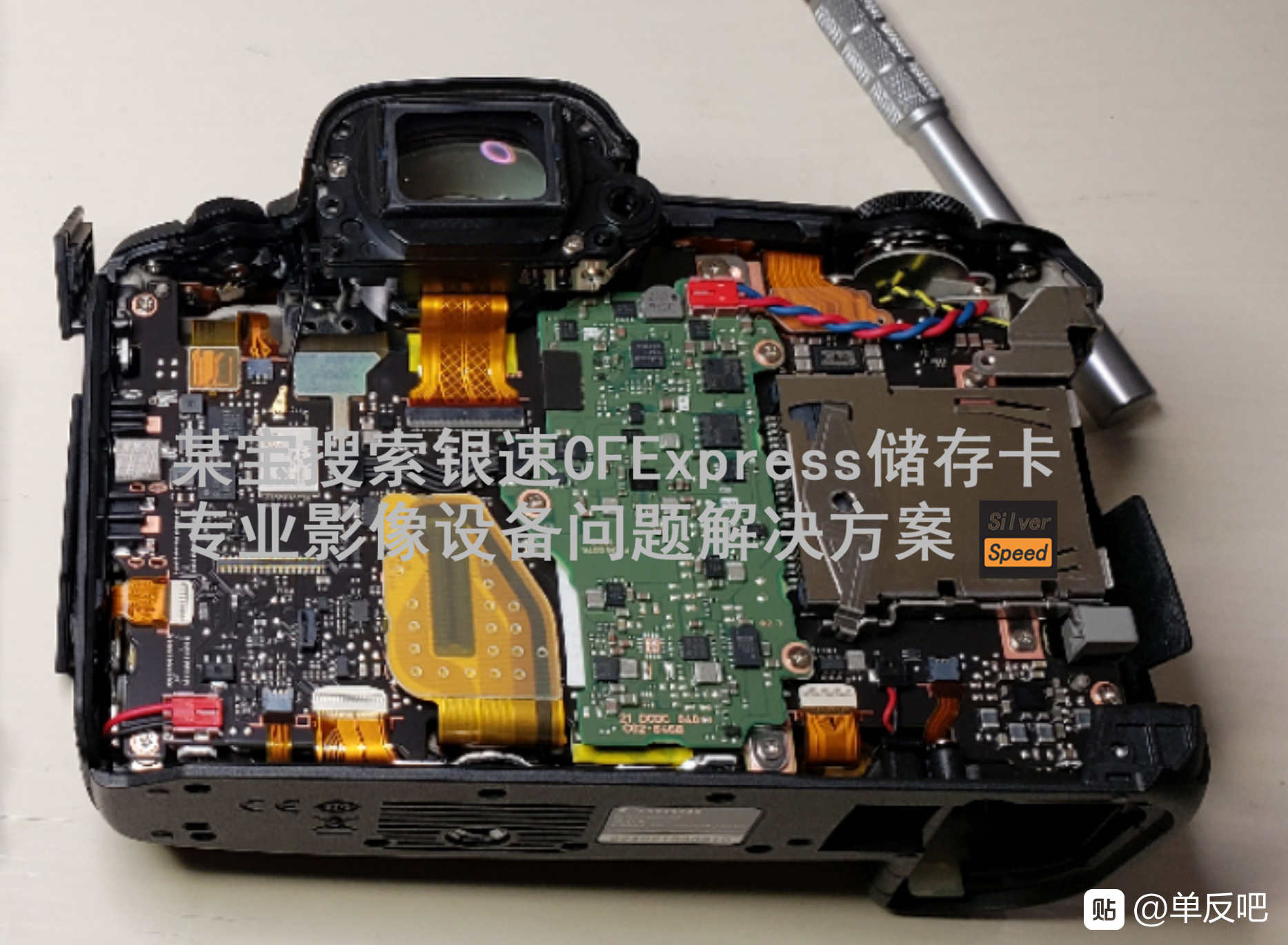

Chinese engineer updates the EOS R5

In a Baidu post, a Chinese engineer takes apart an EOS R5 and finds some curious problems with heat management. From the images, the CPU and memory, while they get hot, do not have a direct path to the magnesium shell from the top as there is a daughterboard sitting in between the path. While...

www.canonnews.com

This is why the bullshit spewing from a certain source is rediculous and bordering on libel and if Canon gets annoyed enough, legal trouble.

and here's the image you should carefully look at

Last edited:

Upvote

0

Could be, I'm hoping that someone open the camera and operate it without fully attached (that's how we test a camea after replacing a component) while having a fan blowing in. That would point out which part generate most heat and whether the recording limit is in the hardware or in the firmwareIt may work. however, I am under an impression that the biggest issue here is the CFE cards are running very hot.

Upvote

0

I think that certain source is damn close to having Canon spend a boat load of money on it.they aren't thermal pads. Why the blazes would you have thermal pads when a daughter card is sitting on top of them? What do you want to do? cook the daughter card?

I updated our article...

Chinese engineer updates the EOS R5

In a Baidu post, a Chinese engineer takes apart an EOS R5 and finds some curious problems with heat management. From the images, the CPU and memory, while they get hot, do not have a direct path to the magnesium shell from the top as there is a daughterboard sitting in between the path. While...www.canonnews.com

This is why the bullshit spewing from a certain source is rediculous and bordering on libel and if Canon gets annoyed enough, legal trouble.

and here's the image you should carefully look at

View attachment 192108

They will either buy him or sue him.

Upvote

0

I think it is possible to put an aluminium sheet in between the chip and the back of the flip screen body to have better heat conductivity between the chip and camera body.

but it might make the camera too hot to touch or may cause other issues. I am pretty sure that they have tried and tested all possible options. interestingly they could have made this camera like 2 mm thicker and make enough room for a proper heatsink.

but it might make the camera too hot to touch or may cause other issues. I am pretty sure that they have tried and tested all possible options. interestingly they could have made this camera like 2 mm thicker and make enough room for a proper heatsink.

Upvote

0

visionrouge.net

Video / Photography, China & Hong Kong

Actually, there is a metal layer between the pad and the second board on top.they aren't thermal pads. Why the blazes would you have thermal pads when a daughter card is sitting on top of them? What do you want to do? cook the daughter card?

I updated our article...

Chinese engineer updates the EOS R5

In a Baidu post, a Chinese engineer takes apart an EOS R5 and finds some curious problems with heat management. From the images, the CPU and memory, while they get hot, do not have a direct path to the magnesium shell from the top as there is a daughterboard sitting in between the path. While...www.canonnews.com

This is why the bullshit spewing from a certain source is rediculous and bordering on libel and if Canon gets annoyed enough, legal trouble.

and here's the image you should carefully look at

View attachment 192108

So, the 2 pads ARE thermal pad. The guy who open it even added some thermal paste to touch the processor also as Canon did not.

It's a very weird choice indeed.

The worst is that the recording time did not increase despite a actual thermal measurement completely acceptable for any electronic component.

The most acceptable explanation is that Canon put a timer to stop recording anyway after a certain duration, whatsoever the temperature.

IT may explain why there is no thermal management on the design.

If the recording time is always cut off, there is no need to go for something sophisticated.

Attachments

Upvote

0

The worst is that the recording time did not increase despite a actual thermal measurement completely acceptable for any electronic component.

The most acceptable explanation is that Canon put a timer to stop recording anyway after a certain duration, whatsoever the temperature.

IT may explain why there is no thermal management on the design.

If the recording time is always cut off, there is no need to go for something sophisticated.

you've been listening to EOSHD too much.

you do realize that a heat sink in a sealed space, and a CPU in a sealed space will heat up to the ambient air temperature in the sealed space the same? the core temperatures will be the same?

a heat sink makes zero difference when there's no airflow.

Upvote

0

I used to enjoy Andrew Reid's commentary and articles but I worry that eoshd may now have come down with a case of Canon Derangement Syndrome.

Last edited:

Upvote

0

visionrouge.net

Video / Photography, China & Hong Kong

Airflow if the best to cool down, I will be agree on that, but this metal part is still useful to bring heat all over the body and increase the overall air exchange with the outside air.you do realize that a heat sink in a sealed space, and a CPU in a sealed space will heat up to the ambient air temperature in the sealed space the same? the core temperatures will be the same?

a heat sink makes zero difference when there's no airflow.

Any heat sink will help reducing temperature exchange and avoid a very hot spot which could be dramatic.

I have such metal part on top of my computer SSD, and there is no airflow from the fan there. It's designed by DELL. You can clearly see the pad and the metal part on top of it. There is a plastic cover on top of this, so no air is actually running around.

I also design time-lapse system without any cooling and adding such pad between the warm spot to diffuse it all over the enclosure clearly helps reducing heat.

My electronic is completely sealed.

Attachments

Upvote

0

Airflow if the best to cool down, I will be agree on that, but this metal part is still useful to bring heat all over the body and increase the overall air exchange with the outside air.

Any heat sink will help reducing temperature exchange and avoid a very hot spot which could be dramatic.

Yes, but once that air heats up, even the heat sink will heat up and the two will reach the same temperature. Once that does, it stays there. the cool down time will be very long. in the end, it doesn't buy you much. The delta T between that and the outside ambient temperature will slowly decrease over time, with or without a heat sink. Heat sinks are good for spiky heat - but sustained heat such as recording for minutes of video? it's not going to work. yes ideally, spreading the heat over the camera body is the ideal solution, however, I"m not convinced they are entirely legally allowed to do that.

On top of that, the cards are a major source of heat - this which we know because the damned camera records for hours without the cards in.

A camera is not going to run super hot. It simply can't .. again, something EOSHD can't comprehend, you're not going to run it much past 50C because of the thermal characteristics of a CMOS sensor and the fact that people have to hold these cameras in their hands for long durations of time.

If you have active cooling and/or are allowed to actively shunt as much heat as possible to the outside, then your design rules are different.

Also - be aware that the temperature reading that Andrew is using is what Canon calls the "EFIC temp" which is for speedlights and lens interface, and not the core CPU cores, or even sensor. There is a correlation, but that depends on body design. In other words, it's not like measuring core temp on a processor.

Last edited:

Upvote

0

what are you talking about here? MTBF significantly degrades with temperature increase.Then it's hard to explain why thermal pads on RAM then? And it's still better to have the heat on PCB than on CPU. The solder lead can withstand at least 200 Celsius and up to 350 depend on the type they use. Components like resistors, coils, capacitor could withstand the heat better than CPU.

Upvote

0

Similar threads

- Replies

- 30

- Views

- 1K

- Replies

- 122

- Views

- 18K

- Replies

- 63

- Views

- 32K

- Replies

- 0

- Views

- 2K